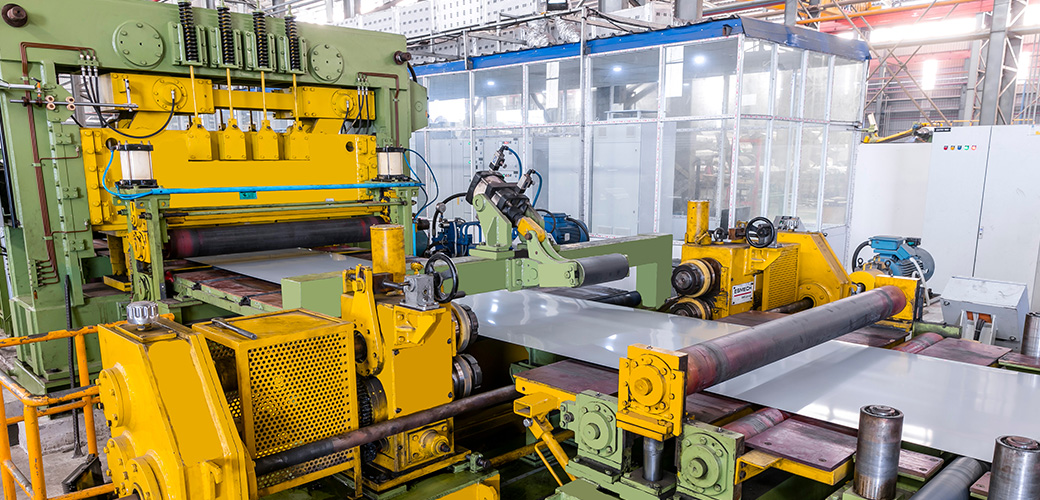

Rewinding (Recoiling) and Trimming Lines

Rewinding (also called as Recoiling) and Trimming are important operations to be carried out after the Cold Rolling of coils.

If the coil has to undergo processes such as Batch annealing, in which the Cold Rolled coil winding tension is not suitable and must be reduced, then the coil must be re-wound with lower tension in the Rewinding Line.

A number of steel coil customers demand exact trimmed CR / Galvanised Coils. To cater to this demand, it is essential to trim the edges of the coil before dispatch to such customers. Both these functions are accomplished in the Esmech Rewinding cum Trimming Line.