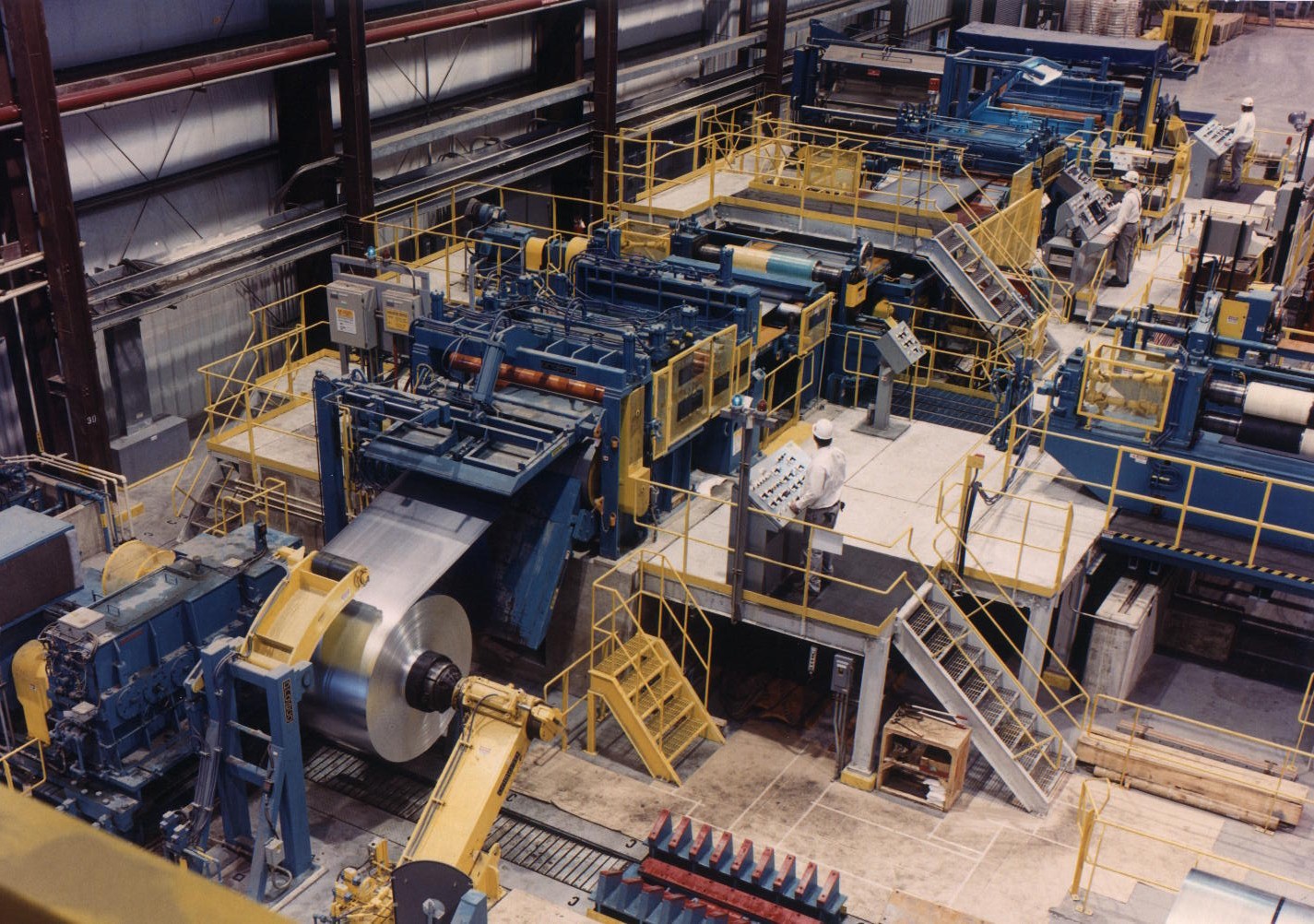

Slitting Lines

Esmech Equipment designs and manufactures slitting lines for Hot Rolled and Cold Rolled ferrous strips as well as non-ferrous strips and foils. Esmech Equipment has a reference of over 65 slitting lines, built over years. The capacity of these lines ranges from 300mm to 2000mm (width) and 0.10mm to 12.0mm (thickness) in strips and 20 to 60 microns in foils, and coil weights upto 40 MT, and speeds upto 300 mpm.

Esmech Equipment offers slitting lines of different designs to exactly suit the customer’s requirements of production capacity, high quality of slit product, automation level, flexibility of operations and budget. The slitting lines can incorporate latest technical innovations such as the Kor-Flex shape correctors, Ura-Flex strip tension unit and the Injecta Type rapid change system for Slitter Heads. Esmech Equipment slitting lines produce superior quality of the slit coils with significantly higher levels of productivity. This goes a long way in providing our customers with a competitive edge in their market.

Some of the important features of Esmech Equipment Slitting Lines are

-

01Kor-Flex shape correctorThe Pro-Eco designed "Kor-Flex" shape corrector operates on the principle of the tension leveller. It results in excellent build up of wound coils with strips having a much enhanced shape. It corrects the edge bow, side bends and also reduces the burrs. The "Kor-Flex" is truly a revolution in the slitting technology.

-

02Injecta type rapid changeoverThis system incorporates mechanised arrangement to changeover the slitter heads in a very small time, thus ensuring a high productivity and flexibility which is crucial especially for service centres. The arrangement can be provided to accomodate upto 4 spare slitter heads.

-

03Ura-Flex strip Tensioning Unit"Ura-Flex" strip tensioning unit offers excellent tensioning of the slit strips, thus ensuring tightly wounded coils. "Ura-Flex" eliminates scratching associated with conventional tensioners and also permits much higher production rates.

-

04AutomationEsmech Equipment can engineer slitting lines to any automation levels required by customers, including computerised diagnostics, production control systems, management information and control systems etc.

-

05Recoiler DrumsEsmech Equipment has a wide range of recoiler drum designs to suit the application, strip thickness and material. Expanded leaf type for thick strips (1.20mm and thicker), Concentric collapse six segments three wedges for thin strips(0.30 to 1.20mm) and Concentric positive collapse six segments six wedges for very thin strips(0.30mm and thinner) are most suited. Replacable recoiler drums with very low changeover time is one ofEsmech Equipment 's special design features.

-

06Edge-TrimmingEsmech Equipment also manufactures edge-trimmers. The edge-trimmer heads can be injecta-mounted, inter-changeable with the slitter heads or can be buitl into dedicated edge-trimming lines. Such dedicated lines are manufactured upto a speed of 600 mpm. Esmech Equipment has also installed an edge-trimmer arrangement right in the roll-bite of an Aluminium foil rolling mill. Esmech Equipment slitting lines are in operation in many countries including Germany, Singapore, Phillipines, China, Kenya etc.